Replacement Wear Parts Self-cleaning Mesh Screen For Crushed Stone Applications

Specifications

Self cleaning screen mesh is made of high carbon steel wire, spring steel wire and stainless steel wire. It can

offer effective solutions to difficult sizing and aggregate separation conditions, such as the blinding and plugging.

Self cleaning screen mesh can separating and screening the wet and moist materials. It is widely used in the

separating materials in the mining, quarry and other industries.

There are four types of self cleaning mesh screen.

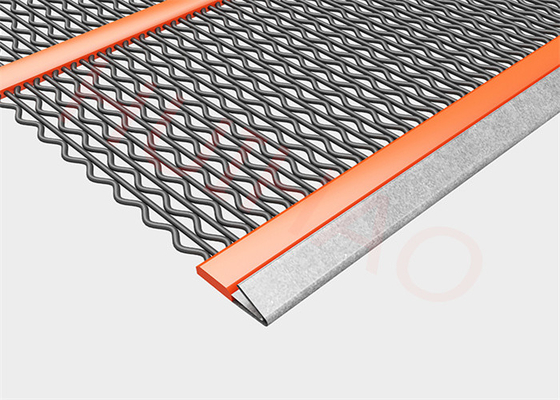

>>> Diamond Opening Self-cleaning Mesh Screen

It is the most popular self-cleaning screen. It is similar to traditional square openings meshes, but with greater open

area and increased throughput, providing precise material stratification and cleaner product.

Diamond shape self-cleaning is consist of crimped round wires bond togther by polyurethane bars creating the 'Square'

or 'Diamond' openings. This type of screens serves all the functions of traditional square woven wire mesh, by providing

precise sizing control and increase open area. What's more is that the diamond self-cleaning screen is able to eliminate

blinding, pegging and clogging problems due to its special design and structure. Each wire will vibrate at different frequency

during screening, and this is what creates the self-cleaning effects of all our self-cleaning series.

1. Eliminate blinding and clogging

2. Higher open area than traditional square mesh

3. Increase production and lower costs

4. Accurate sizing

5. Wear resistance, corrosion resistance

6. High screening efficiency – up to 40 % more through put

|

|

| Item No. |

Opening(mm) |

Wire(mm) |

Item No. |

Opening(mm) |

Wire(mm) |

Item No. |

Opening(mm) |

Wire(mm) |

| 1 |

2.24 |

0.9 |

57 |

8 |

4 |

113 |

18 |

6.3 |

| 2 |

2.5 |

1.2 |

58 |

8.2 |

4 |

114 |

18.41 |

5 |

| 3 |

2.5 |

1.6 |

59 |

8.5 |

2.5 |

115 |

18.5 |

4 |

| 4 |

2.75 |

2 |

60 |

9 |

2 |

116 |

19 |

3.15 |

| 5 |

3 |

1.2 |

61 |

9 |

2.5 |

117 |

19 |

4 |

| 6 |

3 |

1.6 |

62 |

9 |

3 |

118 |

19.05 |

4.88 |

| 7 |

3 |

1.8 |

63 |

9 |

3.15 |

119 |

19.05 |

5.26 |

| 8 |

3.15 |

1.25 |

64 |

9.5 |

2.5 |

120 |

20 |

3.15 |

| 9 |

3.15 |

1.6 |

65 |

9.5 |

4 |

121 |

20 |

4 |

| 10 |

3.15 |

2 |

66 |

9.53 |

3.05 |

122 |

20 |

5 |

| 11 |

3.5 |

1.6 |

67 |

9.53 |

3.43 |

123 |

20 |

6.3 |

| 12 |

3.5 |

2 |

68 |

9.53 |

3.76 |

124 |

20 |

8 |

| 13 |

3.71 |

1.25 |

69 |

10 |

2.5 |

125 |

20.63 |

5.72 |

| 14 |

4 |

1.6 |

70 |

10 |

3.15 |

126 |

20.64 |

4.5 |

| 15 |

4 |

2 |

71 |

10 |

4 |

127 |

21.85 |

3.15 |

| 16 |

4 |

2.5 |

72 |

10 |

5 |

128 |

22 |

4 |

| 17 |

4.41 |

2 |

73 |

10.46 |

4 |

129 |

22.23 |

4.88 |

| 18 |

4.5 |

1.6 |

74 |

10.96 |

3.15 |

130 |

22.23 |

5.26 |

| 19 |

4.5 |

2.5 |

75 |

11.2 |

2.5 |

131 |

22.23 |

5.72 |

| 20 |

4.76 |

1.37 |

76 |

11.2 |

3.76 |

132 |

22.4 |

4 |

| 21 |

4.76 |

1.83 |

77 |

11.2 |

4 |

133 |

22.4 |

5 |

| 22 |

4.76 |

2.03 |

78 |

11.2 |

5 |

134 |

22.4 |

6.3 |

| 23 |

5 |

1.6 |

79 |

11.5 |

5 |

135 |

22.4 |

8 |

| 24 |

5 |

2 |

80 |

12 |

2.5 |

136 |

23.81 |

4.88 |

| 25 |

5 |

2.34 |

81 |

12 |

3.15 |

137 |

24 |

3.15 |

| 26 |

5 |

2.5 |

82 |

12 |

4 |

138 |

24 |

4 |

| 27 |

5 |

3.15 |

83 |

12 |

5 |

139 |

25 |

3.15 |

| 28 |

5.3 |

3.15 |

84 |

12.5 |

3.15 |

140 |

25 |

4 |

| 29 |

5.4 |

2 |

85 |

12.5 |

4 |

141 |

25 |

5 |

| 30 |

5.5 |

3.15 |

86 |

12.5 |

5 |

142 |

25 |

6.3 |

| 31 |

5.6 |

2 |

87 |

12.7 |

3.05 |

143 |

25 |

8 |

| 32 |

5.6 |

2.5 |

88 |

12.7 |

3.15 |

144 |

25.35 |

5.72 |

| 33 |

5.6 |

2.8 |

89 |

12.7 |

3.76 |

145 |

25.4 |

4 |

| 34 |

6 |

2 |

90 |

12.7 |

4.11 |

146 |

25.4 |

4.11 |

| 35 |

6 |

2.5 |

91 |

12.92 |

5 |

147 |

26.5 |

6.3 |

| 36 |

6 |

3 |

92 |

13 |

3.15 |

148 |

27 |

6.3 |

| 37 |

6 |

3.15 |

93 |

13.2 |

2.5 |

149 |

28 |

4 |

| 38 |

6.3 |

1.6 |

94 |

13.2 |

3.15 |

150 |

28 |

5 |

| 39 |

6.3 |

2 |

95 |

13.2 |

4 |

151 |

28 |

6.3 |

| 40 |

6.3 |

2.5 |

96 |

13.5 |

6.3 |

152 |

28.34 |

5.72 |

| 41 |

6.3 |

3.15 |

97 |

14 |

2.5 |

153 |

29.6 |

6.3 |

| 42 |

6.35 |

1.83 |

98 |

14 |

3.15 |

154 |

30 |

6.3 |

| 43 |

6.35 |

2.34 |

99 |

14 |

4 |

155 |

31.5 |

6.3 |

| 44 |

6.35 |

2.67 |

100 |

14 |

5 |

156 |

35.5 |

6.3 |

| 45 |

6.35 |

3 |

101 |

14.29 |

4.11 |

157 |

36 |

10 |

| 46 |

6.8 |

3 |

102 |

15 |

3.15 |

158 |

38.1 |

6.3 |

| 47 |

7 |

2 |

103 |

15 |

4 |

159 |

40 |

8 |

| 48 |

7.1 |

2.5 |

104 |

15.88 |

4.11 |

160 |

40 |

10 |

| 49 |

7.1 |

3.15 |

105 |

16 |

3.15 |

161 |

45 |

8 |

| 50 |

7.1 |

4 |

106 |

16 |

4 |

162 |

45 |

10 |

| 51 |

7.5 |

2.5 |

107 |

16 |

5 |

163 |

50 |

10 |

| 52 |

7.94 |

2.67 |

108 |

17 |

3.15 |

164 |

55 |

10 |

| 53 |

8 |

2 |

109 |

17.46 |

4.11 |

165 |

62 |

10 |

| 54 |

8 |

2.5 |

110 |

17.5 |

3.15 |

164 |

55 |

10 |

| 55 |

8 |

2.8 |

111 |

18 |

4 |

165 |

62 |

10 |

| 56 |

8 |

3.15 |

112 |

18 |

5 |

|

|

|

>>> Triangle Opening Self-cleaning Mesh Screen

Unique combination of crimped and straight wire form the triangular opening shape to absorb impact, and improve

accuracy of sizing. This is a perfect replacement of traditional fine mesh.

Triangle opening screen, is like the diamond opening screen, with an extra straight wire in between every crimped wire

which forms the triangle openings on the screen. It is designed to replace traditional fine mesh to better reduce blinding.

The triangle structure also reinforce the screen for high impact and heavy load screening.

1For high impact, heavy load screening

2Could replace trtaditional fine mesh to betther reduce blinding

3Last over three times longer than other standard screens

| Item No. |

Opening(mm) |

Wire Size(mm) |

Item No. |

Opening(mm) |

Wire Size(mm) |

| 1 |

1.2 |

1.2 |

18 |

5.6 |

3.15 |

| 2 |

1.3 |

0.9 |

19 |

6 |

4 |

| 3 |

1.25 |

1.2 |

20 |

6.35 |

2.67 |

| 4 |

1.3 |

1.2 |

21 |

6.35 |

3.15 |

| 5 |

1.4 |

1.2 |

22 |

7.92 |

3.15 |

| 6 |

1.6 |

1.4 |

23 |

7.94 |

2.34 |

| 7 |

1.8 |

1.2 |

24 |

8 |

2 |

| 8 |

2 |

1.6 |

25 |

9 |

3.15 |

| 9 |

2.5 |

1.2 |

26 |

12.5 |

4 |

| 10 |

2.5 |

1.6 |

27 |

12.5 |

5 |

| 11 |

2.5 |

2.5 |

28 |

12.5 |

6.3 |

| 12 |

2.75 |

2 |

29 |

14.29 |

4 |

| 13 |

3.15 |

2.5 |

30 |

15.88 |

4 |

| 14 |

4 |

3.15 |

31 |

16 |

5 |

| 15 |

4.75 |

3.15 |

32 |

16 |

6.3 |

| 16 |

4.93 |

4 |

33 |

20 |

6.3 |

| 17 |

4.98 |

3.15 |

|

|

|

>>> Wave Opening Self-cleaning Mesh Screen

Made with crimped wires placed parallel to each other, best used for severe blinding application, large open area

offers effective sizing control, ideal for the removal of super fine materials and etc.

Like all the other self-cleaning series, wave opening screen prevents clogging, blinding and pegging. It provides

maximum throughput in severe blinding conditions and offer some sizing control. Ideal for removing fines or for

screening dry manufactured sand, agricultural lime, mulch and wood chips. Could also increase production in screening

wet or adhesive lightweight materials.

1. Eliminate severe blinding and clogging situation

2. Increase open area than Diamond openings

3. Maximum throughout

4. Ideal for removing fines

| Item No. |

Opening(mm) |

Wire Size(mm) |

Item No. |

Opening(mm) |

Wire Size(mm) |

| 1 |

3.18 |

1.37 |

6 |

6.35 |

2.03 |

| 2 |

4.76 |

1.83 |

7 |

7.94 |

2.34 |

| 3 |

3.15 |

2 |

8 |

11.2 |

3.55 |

| 4 |

4 |

2 |

9 |

17.5 |

5 |

| 5 |

6 |

2 |

|

|

|

>>> Harp Opening Self-cleaning Mesh Screen

Designed to have the maximum open area, most efficiently in removing sand, gravel, topsoil, fines and etc.

The Self-cleaning Harp screen has the maximum open area in all self-cleaning series. Like traditional harp/piano screen,

the self-cleaning screen is best for desanding or removing fines while mantaining material in size. It is most efficiently in

dry screening of sand, gravel, loam, topsoil, mulch, compost, golf sand and more.

1. Maximum open area

2. Significantly increase efficiency in dry screening of sand gravel, loam, topsoil, mulch, compost, golf sand and removing

of fines.

3. Offer some sizing control

| Item No. |

Opening(mm) |

Wire Size(mm) |

Item No. |

Opening(mm) |

Wire Size(mm) |

| 1 |

4 |

2 |

11 |

5 |

3.15 |

| 2 |

5 |

2 |

12 |

12.7 |

3.43 |

| 3 |

8 |

2 |

13 |

12.7 |

3.76 |

| 4 |

10 |

2 |

14 |

6 |

4 |

| 5 |

12 |

2 |

15 |

15.88 |

4.11 |

| 6 |

5 |

2.34 |

16 |

12 |

5 |

| 7 |

5 |

2.5 |

17 |

16 |

6 |

| 8 |

6.35 |

2.67 |

18 |

22.4 |

8 |

| 9 |

9.53 |

3.05 |

19 |

25 |

8 |

| 10 |

12.7 |

3.05 |

|

|

|

Features

Control strictly for the sizing.

Self-cleaning ability and less maintenance.

Three different types - W mesh, H mesh and D mesh.

Reduce the blinding and plugging.

Wear and abrasion resistance.

Producing tighter specifications and having the ability to self-clean.

Customized width and length is available.

Applications

Quarrying Industry

Mining Industry

Coal Production

Crushed Stone Applications

Screening Gravel

Organic Fertilizer Production

Topsoil Production

Screening Sand

Package

1. 20 pieces per wooden pallets. 2.25pallets per 20ft container 3. to be your request

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!