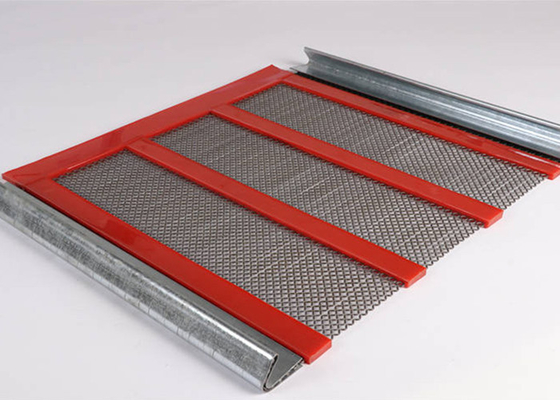

Anti Blocking Poly Ripple Self-cleaning Screens For Aggregate Processing

Quick Details

Poly ripple screens can be manufactured with apertures between 2.5mm and 32mm and are very efficient

across this range. Ripples can be manufactured with a larger aperture where necessary but their efficiency

strength lies within this range. In contrast, other screening media formats have much narrower bands of

efficiency. Straight rubber or polyurethane screening types are often only efficient within a far narrower

band of apertures in heavy impact areas or are only suited to particular screening conditions, wet or dry.

This means if conditions change, the site may be required to change screens to continue producing efficiently.

Poly ripple screens were originally designed to take the self-cleaning properties of the standard wire ripple

screen, developing it into a longer lasting screen while delivering a more precise cut point, so it is in wet

conditions that they truly come into their own. The secondary vibratory movement within the ripple screen

allows even wet, sticky product to move through the system, with less likelihood of the screen being blocked

up compared with the standard square weave mesh.

Specifications

Material: High carbon steel wire, spring steel wire, manganese steel and stainless steel.

Wire diameter: 0.5mm - 5mm.

Opening size: 2.5mm-32mm

(Special size also could be customized as your request.)

Surface treatment: Galvanized or painted.

Edge: Hooked edge is available.

There are three types of anti blocking poly ripple screens

W Type

W type is specifically engineered and designed to reduce blinding and plugging conditions when the use of

conventional square opening wire cloth is not acceptable. The W type poly ripple screen accurately controls

material sizing, both undersized, similar sized and oversized materials, while staying clean and remaining

efficient.

W type works on the principle of wire movement. It is designed with alternating straight wire and crimped wire.

The crimped wire can decide the aperture size. Both straight and crimped wires are alternately woven together

with binding wires, which are placed directly over the longitudinal support bars.

To improve the wear resistance, the binding wires can be covered with abrasion-resistant polyurethane.

But in the hot mix batch asphalt plants, where accurate sized material is required and blinding conditions are

moderate, the polyurethane is not available.

|

|

| W type of poly ripple self-cleaning screens |

Binding wire covered with polyurethane can improve the wear life.

|

D Type

The D type is designed with precisely crimped wires and woven into diamond shaped openings. D type poly

ripple screen has more effective open area, because there isn’t the straight wire, which is existing in the W type.

D type is ideal for the medium and light materials. It is effectively controls the materials sizing through the equal

openings. D type screen can do an excellent job no matter how strict the material sizing requirements.

|

|

| D type of poly ripple self cleaning screens |

Polyurethane can protect the binding wire and improve the wear resistance. |

H Type

The H type of poly ripple screen mesh is made of several horizonal and parallel crimped wires. It looks like

the herringbone pattern, which can offer better sizing control than D type mesh and W type mesh by eliminating

more flats and elongates. H type poly ripple screen is ideal for the situations where material sizing is important,

but not very critical. It is proven high effective in the extreme blinding screenings, such as the asphalt screening

applications.

|

|

| H type of poly ripple self cleaning screens |

H type screen has better opening area than D type and W type.

|

Features

Control strictly for the sizing.

Self-cleaning ability and less maintenance.

Three different types - W mesh, H mesh and D mesh.

Reduce the blinding and plugging.

Wear and abrasion resistance.

Producing tighter specifications and having the ability to self-clean.

Customized width and length is available.

Applications

Self cleaning screens effective screening all kind size of the most wet, moist material using in mining, quarry,

aggregate processing industries.

Package

1. 20 pieces per wooden pallets. 2.25pallets per 20ft container 3. to be your request

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!